Despite all the skiing I documented during my year, I also did manage to get plenty of work done!

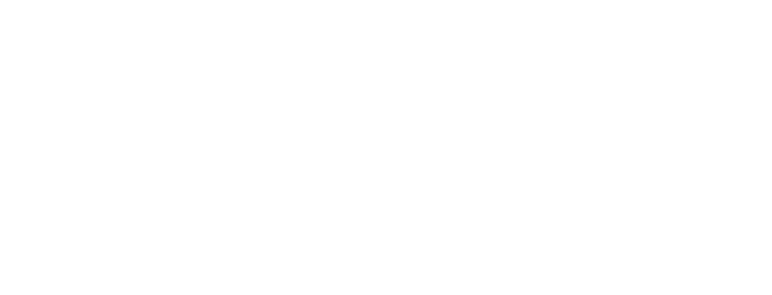

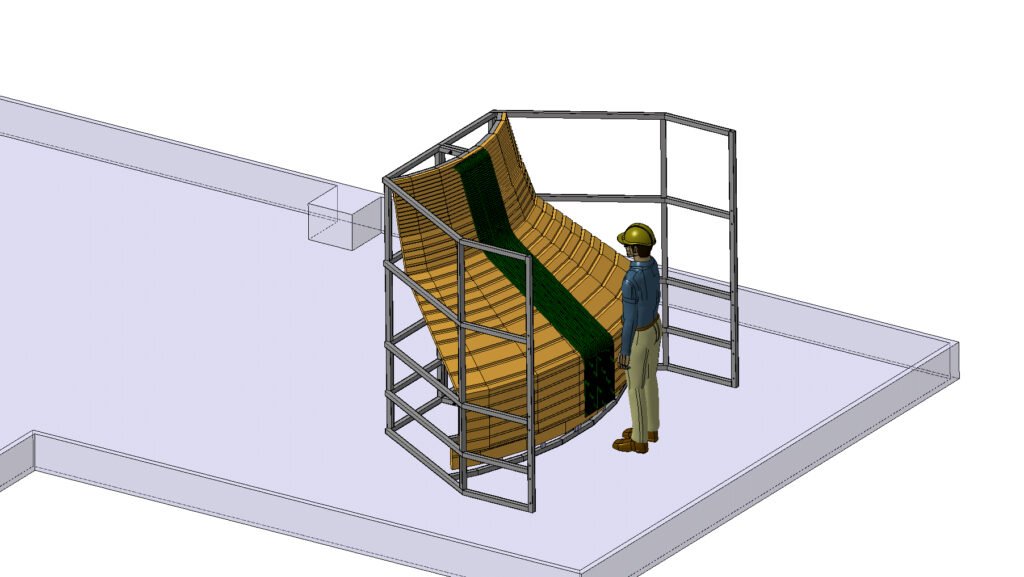

I was involved in two major projects at CERN. I was responsible for designing and manufacturing a 1:1 scale integration model of part of the detector for cooling and testing purposes. My tasks included:

- Ensuring services can be routed in given space

- Installation sequence of cooling pipes, services and thermal screen (troubleshooting)

- Thermal screen integration model consideration

- Mock rotation and transport sequence tasks

- Creation of CAD designs

- FEA analysis structural integrity

- 2D technical drawings

- Liaising with manufacturer and developing construction sequence

Photos Courtesy of Karol Rapacz

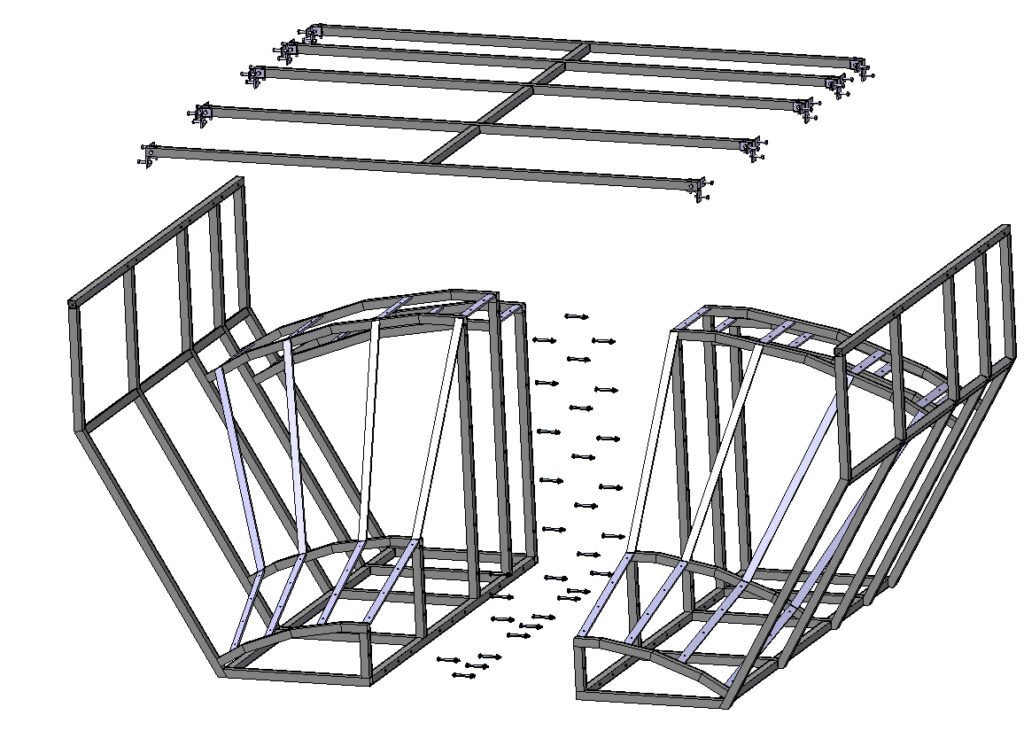

Alongside this, I co-designed the services feedthrough design proposal for the HGCAL Endcap for the Phase 2 LHC. My roles for this project included:

- Service feedthrough methods and sealing functions

- Routing of services inside cold volume (compatible with assembly sequence layer by layer, and optical and CO2 installed last)

- Routing of services outside the cold volume into the cable channels on top of the endcap nose brackets

- Packing factor of cables and layout efficiency

- Connector options

- Heat transfer calculations and simulations experience based on copper cross section and feedthrough materials

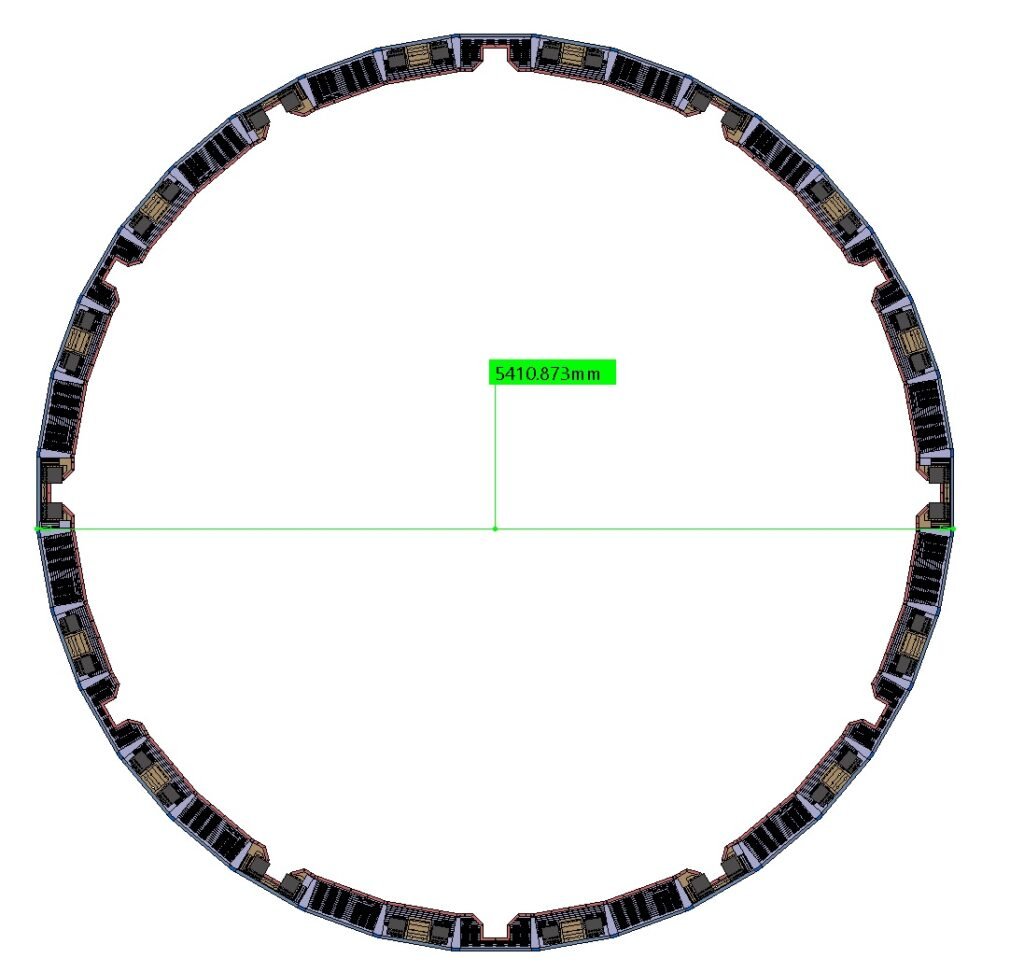

Culminating in a 3D CAD model integrated into the master CMS HGCal assembly as seen below

Feedthrough section (approximately 30°)

Integrated into HGCAL Model

Full 360° Model