What isn’t there to like?

Generative Design is not the solution to all problems faced by engineers and architects today. It relies heavily on an experienced user to input the correct loads (forces) and constraints and does not possess ‘common sense’.

Simply put, rubbish in equals rubbish out.

Unrealistic Solutions?

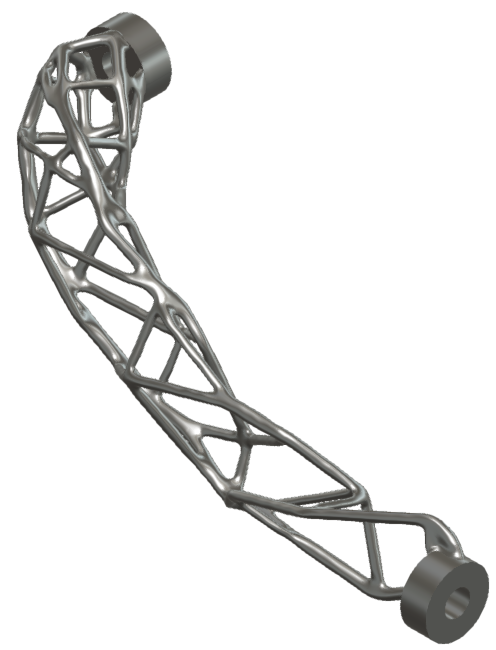

There is also difficulty when it comes to manufacturing. Manufacturing capability limits the freedom to which parts can be designed. Theoretical structurally-optimum designs are a complex web of interconnecting material, existing only where needed. An example is shown below:

Fusion 360 allows for the manufacturing method to be specified and considers the limitations so that any solution can be theoretically produced. However, in reality, this is not always possible and an experienced engineer will be needed to apply their expertise and conclude whether it can be manufactured.

Often, simpler solutions produced by the generative design software are selected due to the reduced manufacturing cost and complexity, which does not use the algorithm to its full potential. A cost/complexity trade-off will always need to be considered, which does not make generative design a useful tool for every case.